Posted on January 20, 2020 – April 22, 2021 by The Priebe’s Creative Woodworking TeamFor nearly 25 years, our team of craftsmen at Priebe’s Creative Woodworking has designed, built, and installed well over a thousand kitchens and baths. With this experience comes the knowledge to help our clients make the best decisions possible with their hard-earned investment so they can have the kitchen of their dreams that is built to last for generations.One of the most important factors to consider with your kitchen remodel is how your cabinetry is constructed. While cabinetry may look similar on the outside, not all cabinets are built the same. This is why it’s important to know your options for cabinetry construction before deciding on the style of your cabinetry and the material used.

Face-frame cabinetry is commonly known as American-style or traditional cabinetry because cabinet boxes are traditionally built with a wood face frame (typically 1-1/2 inch) on the front side of the cabinet box. As its name inherently states, face-frame cabinetry box construction resembles a picture frame and offers more rigidity because the doors of the cabinet are attached to the face frame itself.

Gaining in popularity, frameless cabinetry is often used in modern or European-style kitchens for a simple, sleek look. Also called full access cabinetry, frameless cabinets do not have a face frame on the front of the cabinet box. This frameless construction offers more interior space and closer reveal lines between the doors and drawer fronts. If you’re trying to conserve space in a smaller kitchen, going frameless can increase your storage capacity by up to 10%!

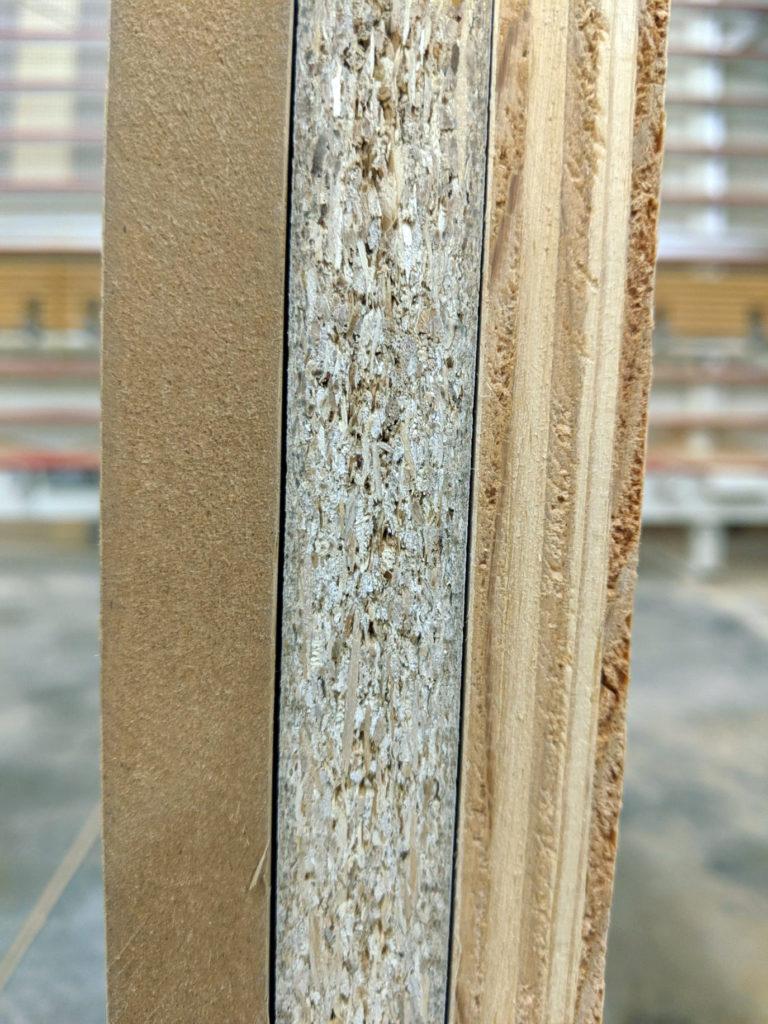

You may have heard the saying, “It’s what’s on the inside that counts.” This definitely comes into play when choosing what material to use for the sides of your cabinet boxes. The most common materials used are Plywood, Particle Board, and MDF (Medium Density Fiberboard).

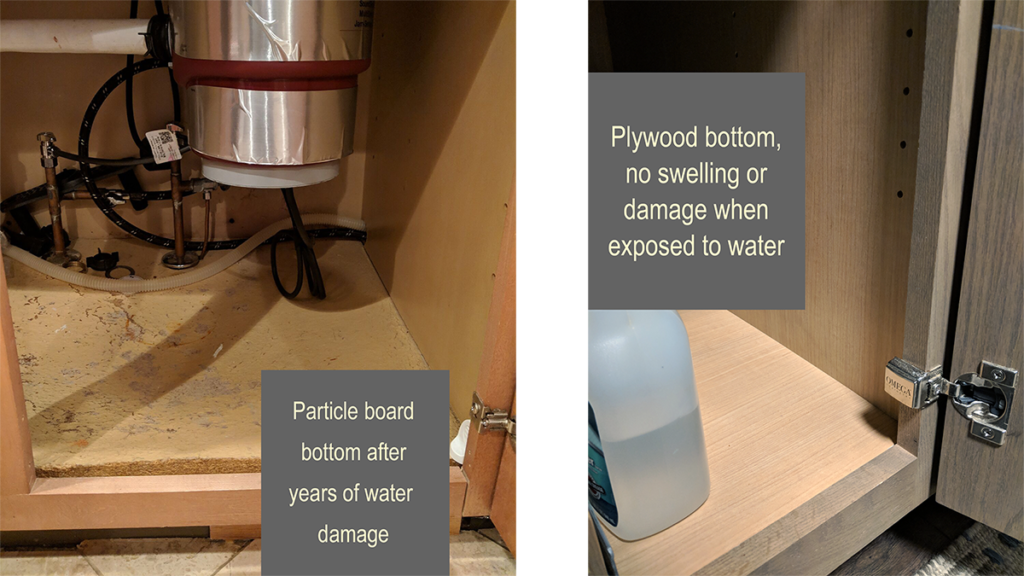

For most cabinet companies, plywood constructed cabinet boxes typically cost about 10-15% more than particle board cabinetry. Plywood is made with thin layers of wood glued together, alternating the grain of wood for stability. If you desire the beauty and feel of natural wood, plywood displays the intricacies of the wood grain, knots, and mineral streaking that you won’t find with particle board or MDF constructed cabinetry. Plywood is also known for being stronger than other cabinetry materials. It’s durable enough to withstand encounters with water and frequent use over time, holding screws, nails, and mechanical fasteners more securely than particle board and other cabinetry materials.

Particle board is made with compressed wood chips glued together into panel sheets. Generally, particle board is a practical option if you’re looking for a more short-term solution and trying to keep costs down. Based on appearance alone, particle board and plywood cabinetry may look similar, but there is a vast difference in how long they’ll last. The difference in quality can become visible even after just a few years of daily use, as you may start to notice the hinges and drawer guides loosening in a particle board cabinet side. Most of us have experienced trying to tighten a screw into a particle board shelf or cabinet side, and it essentially becomes “stripped out.” The screws no longer hold into the cabinet sides because the particle board (constructed of wood chips) begins to crumble. Particle board cabinets also can easily be damaged by water and steam since the material will swell if exposed to water for an extended period of time. For this reason, it’s best to avoid installing it under kitchen or bathroom sinks.

MDF cabinetry is engineered from dense wood fibers and adhesives being compressed. MDF is denser, stronger, and more durable than particle board. MDF is typically vulnerable to water damage in areas with frequent exposure to water. However, you can ask for moisture-resistant MDF in areas exposed to moisture, like under a sink or near a dishwasher that emits steam. One area where MDF excels is that it provides a smooth surface for painting since it does not have a noticeable wood grain or knots that will show through a coat of paint.

All materials used in cabinet construction have their advantages and disadvantages, depending on your unique goals for your project. When choosing your cabinetry cases, it’s important to consider the following:

1) Your goals for longevity. Is this a solution for now, or do you want your kitchen to last for decades?

2) How moisture-resistant do you want your cabinets to be to protect your investment?

3) Your budget. A kitchen remodel is one of the most expensive investments you can make in your home. So it’s incredibly important to start by setting a realistic budget for your project. Generally for cabinetry and countertops, it’s recommended you should plan to spend at least 12-15% of the total value of your home if you want to get a 1:1 return on your investment when reselling your home.If you’re thinking about new cabinetry for your home and have any questions about your unique project, please feel free to contact us – We’d love to have the opportunity to help any way we can!The Most Costly Kitchen

Remodeling Revolution: Changing Routines